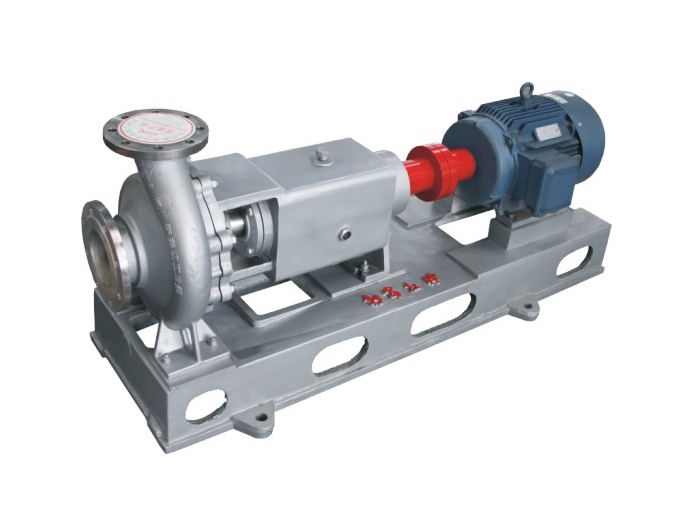

HT chemical channel pump is developed by us with special design elements based on the pump making technique advanced both at home and abroad. The pump employs single-stage single-suction suspended structure and complies, in respect of its performance parameters, with GB5662(IDT ISO2858).

The world leading hydraulic model is combined with the characteristics of two phase flow pump to develop such a new chemical channel pump with high efficiency and solid conveying capability. As an energy saving product, it has 5%~10% higher efficiency than TW and open vane pump. Its structural design refers to ANSI standard for larger axial diameter and shorter cantilever to reduce vibration and broken axles of TW pump and for higher stability to decrease maintenance and operation costs. The impellers of wide flow channel could easily carry the slurry. Besides, high-quality mechanical seal is used for it. The product is a type of preferred conveying equipment for easily crystallizable and multiple solids in calcined soda, chloralkali, salt making, smelting, paper making, environmental and other industries.

Applications

Suitable for conveying chemical slurry with particles below 3-5mm and solid content below 20%,for instance, for alkali production and conveying salt slurry and salt sludge of inorganic salt; conveying ore pulp, mother liquor and crystal seeds in nonferrous metallurgy, slurry sediment in the furnace and bentonite; conveying green mud, lime mud, black liquid and milk of lime in paper making; conveying all middleware, lactic acid, citric acid, food additives and fermented pulps in ferment industry; for environmental protection and conveying all industrial waste waters.

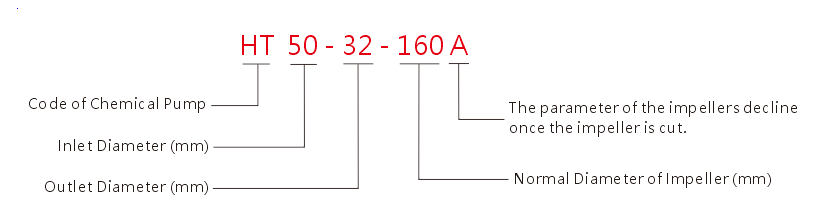

Model Specification

FPL Series Plastic Inline Pump

FPL Series Plastic Inline Pump