The pump, a standardized chemical process pump upgraded and improved from IH pump, employs single-stage single-suction suspended structure and complies, in respect of its performances, parameters and dimensions, with GB5662 (IDT ISO2858). The design IJ chemical process pump takes advanced hydraulic model for high efficiency and energy saving. Its structural design refers to ANSI standard for large axial diameter, shorter cantilever and higher stability. Its working temperature is 175°C. It is suitable for conveying liquids with suspended particles below 3mm and solid content below 5% and is widely applied in alkali, acid, petrochemical, environmental and other industries.

Applications

1.Alkali industry: mother liquor of ammoniacal brine for production of calcined soda, ammonia and soda, caustic alkali for production of chloralkali, chlorine products, chlorate, hypochlorite etc.

2. Nonferrous metallurgy: conveying electrolyte of electrolyzed copper and nickel, acid mist/liquor for cobalt production, ore pulp for zinc production, ammonium vanadate for vanadium production and acid thiourea liquid for gold production.

3. Steel industry: plating, acid washing, waste acid treatment.

4. Acid industry: nitric acid, sulphuric acid, hydrochloric acid, phosphoric acid, acetic acid etc.

5. Petrochemical: petroleum refined aldehydes, alky| benzene production.

6. Synthetic fiber and plastic industry: production, weaving and dyeing of polyester fiber and PVC.

7. Paper making: conveying boiling liquid of pulp and bleaching liquid.

8. Chemical fertilizer industry: production of urea and ammonium nitrate.

9. Pharmaceutical: production of medicine and pesticide.

10. Environmental protection: conveying acid mist/liquor.

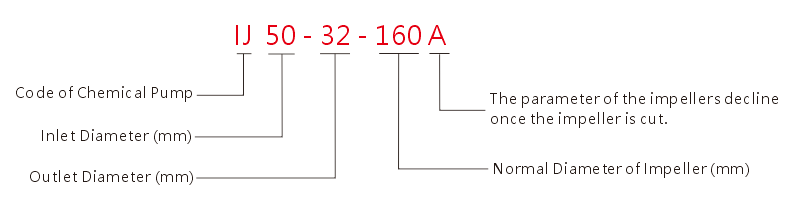

Model Specification

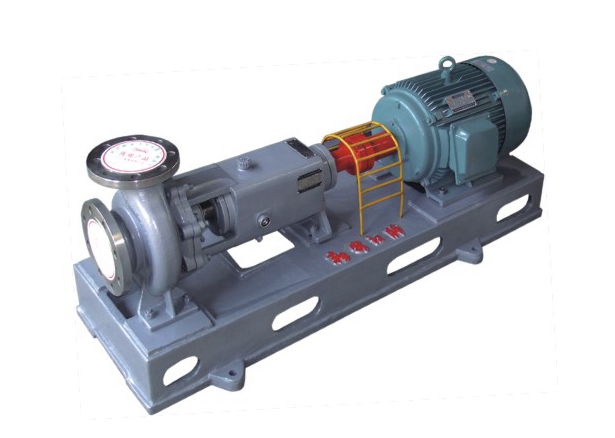

Structural Representation

.png)

IHF4 Series Fluoro-plastic Centrifugal Pump

IHF4 Series Fluoro-plastic Centrifugal Pump